पà¥à¤°à¥ तरह सॠसà¥à¤µà¤à¤¾à¤²à¤¿à¤¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सà¥à¤à¥à¤°à¥à¤ª पà¥à¤¶à¤°

पà¥à¤°à¥ तरह सॠसà¥à¤µà¤à¤¾à¤²à¤¿à¤¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सà¥à¤à¥à¤°à¥à¤ª पà¥à¤¶à¤° Specification

- तापमान सीमा

- -10°C to +55°C

- कनेक्टिविटी टाइप

- Wired PLC Interface

- फ्लो रेट

- 120-210 L/min

- पावर सोर्स

- माउंटिंग टाइप

- ऑपरेटिंग प्रेशर

- 180-220 Bar

- सीलिंग टाइप

- एक्सेसरीज़

- Electric Control Panel, Safety Guard, Emergency Stop, Push Button Controls

- उपयोग

- औद्योगिक

- बॉडी मटेरियल

- टाइप करें

- ढकेलने वाला

- स्ट्रक्चर

- Rigid Welded Frame

- प्रॉडक्ट टाइप

- हाइड्रालिक स्क्रैप पुशर

- फ़ोर्स

- हाइड्रॉलिक

- स्पीड

- Variable (Adjustable/Programmable)

- वोल्टेज

- 380V AC (Three Phase)

- वारंटी

- हाँ

- Noise Level

- Less than 75 dB

- Control System

- Programmable Logic Controller (PLC)

- Ambient Humidity

- Up to 85%

- Hydraulic Cylinder

- Bore Diameter 250 mm

- Maximum Pushing Capacity

- Up to 6000 kg/hr

- Weight

- 4500 kg (Approx.)

- Cycle Time

- 60-90 seconds per operation

- Control Panel

- Pre-wired With Digital Display

- Surface Finish

- Corrosion Resistant Powder Coating

- Safety Features

- Pressure Relief Valve, Limit Switches, Overload Protection

- Applicable Standard

- CE Marked, ISO 9001 Certified

- Color

- Industrial Blue/Gray

- Motor Power

- 15-30 HP (Depending on Configuration)

- Oil Tank Capacity

- 400 Liters

पà¥à¤°à¥ तरह सॠसà¥à¤µà¤à¤¾à¤²à¤¿à¤¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सà¥à¤à¥à¤°à¥à¤ª पà¥à¤¶à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- कैश इन एडवांस (CID)

- आपूर्ति की क्षमता

- 10 प्रति महीने

- डिलीवरी का समय

- 2-10 दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About पà¥à¤°à¥ तरह सॠसà¥à¤µà¤à¤¾à¤²à¤¿à¤¤ हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ सà¥à¤à¥à¤°à¥à¤ª पà¥à¤¶à¤°

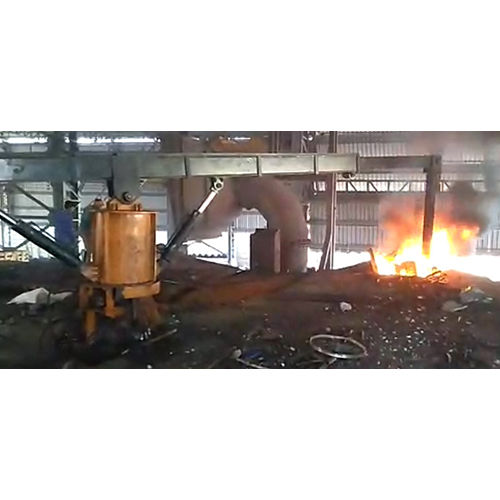

Discover the Fully Automatic Hydraulic Scrap Pusher with a preeminent Programmable Logic Controller (PLC) system engineered for remarkable savings of time and effort. Achieve dazzling productivity with a lofty maximum pushing capacity of up to 6000 kg/hr, supported by a robust 15-30 HP motor and heavy-duty welded steel structure. Reduced noise (less than 75 dB), CE and ISO 9001 certification, and corrosion-resistant powder coating ensure steadfast performance. Effortlessly redeem value with comprehensive safety features, variable speed, and a digital display for seamless operation in diverse industrial environments.

Versatile Applications and Enhanced Features

This Fully Automatic Hydraulic Scrap Pusher is designed for integration in heavy-duty industrial plants, including metal recycling, foundry, and manufacturing facilities. It is used for efficiently pushing and compacting scrap materials, streamlining material handling processes. The equipment features advanced programmable controls, high-pressure hydraulic seals, and a corrosion-resistant structure. Enhanced by customizable speed, emergency stop, and digital monitoring, this system maximizes safety and operational flexibility across demanding usage scenarios.

Reliable Supply, Global Markets, and Order Fulfillment

We guarantee the lowest price without compromising quality, thanks to our robust manufacturing capacity and efficient order completion processes. Transportation is streamlined for timely delivery across all main export markets, including Asia, the Middle East, and Africa. Our sample policy supports buyers seeking reliable evaluation before full-scale orders. Every transaction, from inquiry to delivery, is executed with precision to ensure full customer satisfaction and dependable global supply ability.

Versatile Applications and Enhanced Features

This Fully Automatic Hydraulic Scrap Pusher is designed for integration in heavy-duty industrial plants, including metal recycling, foundry, and manufacturing facilities. It is used for efficiently pushing and compacting scrap materials, streamlining material handling processes. The equipment features advanced programmable controls, high-pressure hydraulic seals, and a corrosion-resistant structure. Enhanced by customizable speed, emergency stop, and digital monitoring, this system maximizes safety and operational flexibility across demanding usage scenarios.

Reliable Supply, Global Markets, and Order Fulfillment

We guarantee the lowest price without compromising quality, thanks to our robust manufacturing capacity and efficient order completion processes. Transportation is streamlined for timely delivery across all main export markets, including Asia, the Middle East, and Africa. Our sample policy supports buyers seeking reliable evaluation before full-scale orders. Every transaction, from inquiry to delivery, is executed with precision to ensure full customer satisfaction and dependable global supply ability.

FAQs of Fully Automatic Hydralic Scrap Pusher:

Q: How does the Fully Automatic Hydraulic Scrap Pusher enhance industrial material handling processes?

A: The pusher automates the task of pushing and compacting scrap materials, streamlining production lines and reducing manual labor, resulting in substantial operational efficiency.Q: What safety mechanisms are integrated into this hydraulic scrap pusher?

A: Safety is prioritized with features such as a pressure relief valve, limit switches, overload protection, safety guard, emergency stop, and push button controls, complying with CE standards.Q: When is it recommended to use this machine in an industrial plant?

A: This machine is ideal for operations requiring high-volume scrap management, such as during continuous production cycles or when compacting large amounts of industrial scrap metal.Q: Where can the Hydraulic Scrap Pusher be installed?

A: The machine is designed for floor mounting in industrial facilities, particularly in metal processing, recycling, and heavy manufacturing environments that demand rigorous material handling.Q: What are the main benefits of reduced noise and corrosion resistance?

A: Reduced noise ensures a safer and more comfortable working environment, while corrosion-resistant powder coating extends the equipments lifespan and minimizes maintenance requirements.Q: How does the programmable logic controller (PLC) contribute to the machines operation?

A: The PLC allows precise, programmable control over cycle operations, speed, and safety functions, enabling customizable performance and easy integration with other plant automation systems.

- Minimum Order Quantity

- Supply Ability

- Delivery Time

- Main Domestic Market

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें